Real-Time Monitoring

Continuous data collection to monitor the condition and performance of equipment in real-time.

Anomaly Detection

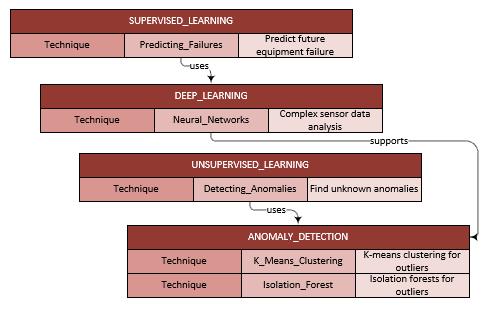

Advanced AI techniques to detect anomalies in equipment behavior, which could indicate potential failures or inefficiencies.

Predictive Analytics

Machine learning models that predict the status of equipment, helping to forecast when maintenance should be performed.

Fault Diagnosis

Automated fault diagnosis to identify the root cause of detected issues, allowing for quick response and resolution

Historical Data Analysis

Analysis of historical data to identify patterns and trends that may indicate future failures, helping to refine predictive models.

Adaptive Learning

Continuous learning from new data to improve model accuracy over time, adapting to changing conditions and equipment aging.

CEDRA’S AI-POWERED PREDICTIVE MAINTENANCE SOLUTION

Cedra’s AI-powered predictive maintenance solutions are transforming asset management and manufacturing by integrating cutting-edge technologies that deliver tangible business benefits.

At the core of Cedra’s offering are advanced machine learning algorithms that continuously analyze data from various sources, including sensors, equipment logs, and operational parameters. This real-time monitoring enables the system to identify early signs of wear, stress, or failure, often long before they become critical. These predictive insights allow businesses to proactively address maintenance issues, avoiding costly unplanned downtime that can disrupt production schedules.

Cedra’s solutions also optimize costs by reducing the frequency of unnecessary maintenance activities. Traditional maintenance models often rely on fixed schedules, which can lead to over-maintaining or under-maintaining equipment. With Cedra’s AI-driven approach, maintenance is performed only, when necessary, based on the actual condition of the assets. This helps extend the lifespan of critical assets while minimizing waste, both in terms of resources and labor.

On a broader scale, Cedra’s AI solutions empower businesses to enhance operational efficiency. By analyzing vast datasets across multiple pieces of equipment and processes, Cedra identifies patterns that are not obvious through manual monitoring. This enables companies to improve resource utilization, such as optimizing energy consumption, and reducing material waste, further driving down operational costs.

Moreover, Cedra’s ability to reduce operational downtime has a direct impact on business continuity. Predictive maintenance ensures that assets are available when needed, avoiding interruptions to production that could lead to missed deadlines or lost revenue. This also enhances customer satisfaction and strengthens a company’s competitive edge in a fast-moving market.

Ultimately, by leveraging AI-driven data analysis, Cedra enables businesses to streamline operations, increase productivity, and support sustainable growth. These solutions are essential for organizations looking to stay ahead in an increasingly data-driven and technology-powered industrial landscape.

SOLUTION DESCRIPTION

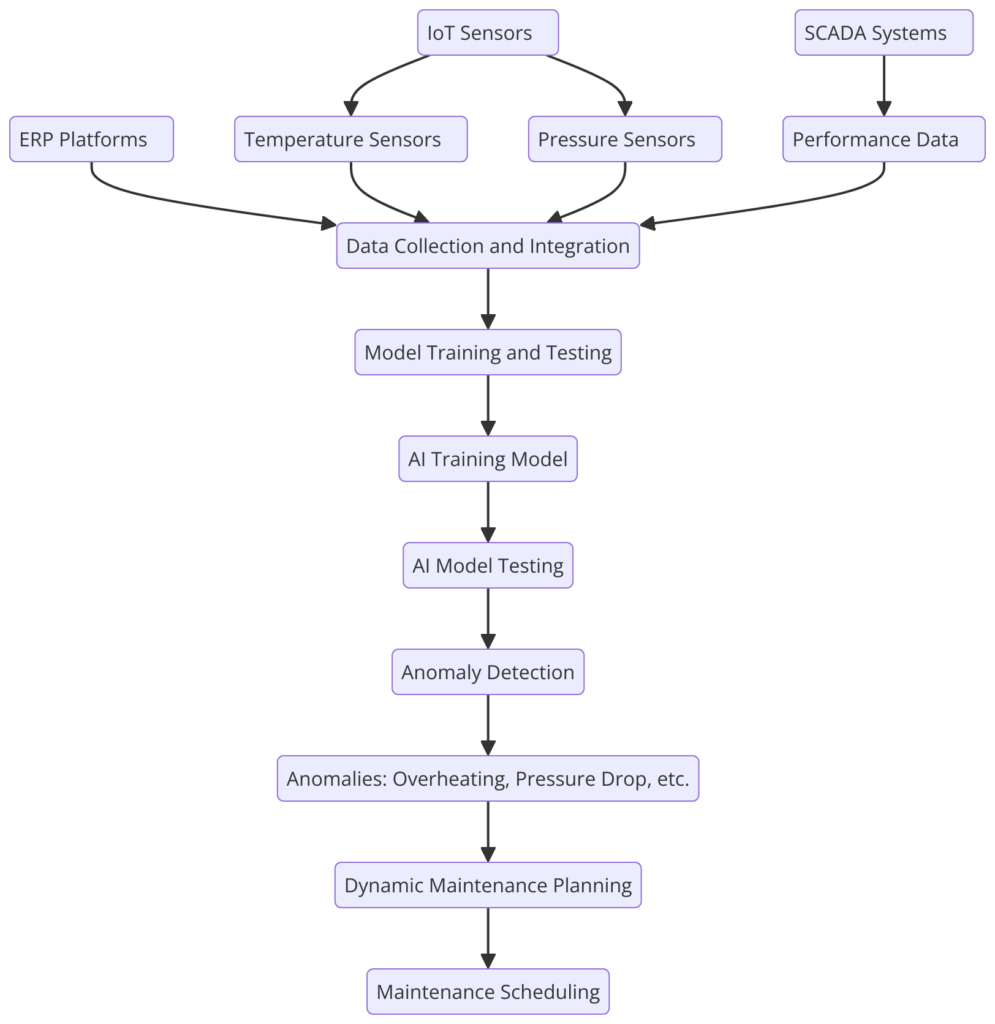

Cedra’s AI-driven Predictive Maintenance (PdM) solution leverages cutting-edge AI algorithms combined with IoT sensor networks to offer precise, real-time insights into the condition of critical assets. By continuously monitoring parameters such as vibration, temperature, pressure, and electrical consumption, the solution can detect subtle changes that are often early indicators of equipment degradation or failure.

The core of Cedra’s PdM solution is its machine learning models, which are trained on vast datasets from industrial operations. These models can recognize patterns and anomalies in the data, predicting potential failures with high accuracy. Advanced analytics, including predictive and prescriptive modeling, ensure that maintenance actions are recommended before failures occur, optimizing asset lifespan and reducing unscheduled downtimes.

Seamless integration with IoT-enabled sensors allows the system to gather data in real-time, sending it to a cloud-based or on-premise platform for processing and analysis. The platform is designed to integrate effortlessly with existing SCADA (Supervisory Control and Data Acquisition) systems, ERP (Enterprise Resource Planning) systems, and CMMS (Computerized Maintenance Management Systems), allowing businesses to consolidate asset monitoring, workflow management, and operational data into a single, intuitive interface.

Cedra’s solution also supports scalability and customization, adapting to the unique operational requirements of various industries, including manufacturing, energy, and transportation. By providing dashboards, KPIs, and automated reporting, businesses can ensure they are making data-driven decisions to enhance maintenance efficiency, minimize operational disruptions, and maximize asset productivity.

In summary, Cedra’s AI-driven PdM solution is designed to revolutionize maintenance strategies by offering actionable insights, increasing operational efficiency, and significantly lowering total cost of ownership.

experience team members amazing it solutions IT involves the physical components and devices used for computing, data storage, and networking. This includes computers, servers, routers, switches, storage devices, and peripheral devices like printers and scanners

Business Flow Process

Cedra’s AI-powered predictive maintenance follows a well-structured business flow

Technical Approaches

Cedra’s AI-powered predictive maintenance is supported by advanced machine learning techniques, including:

amazing it solutions IT involves the physical components and devices used for computing, data storage, and networking. This includes computers, servers, routers, switches, storage devices, and peripheral devices like printers and scanners

Implementation Strategy

Cedra’s implementation process is designed to ensure a seamless transition to AI-powered maintenance. Key steps include:

- Initial Assessment:

A thorough assessment of the client’s operations is conducted to identify challenges and define the scope of the solution. - Data Collection and Integration:

Cedra connects to existing systems, such as IoT sensors and SCADA, to gather real-time data for analysis. - Customization and System Setup:

Cedra customizes its AI models to meet the specific needs of the business, ensuring optimal system performance. - Model Training and Testing:

AI models are rigorously trained on historical data and tested in a controlled environment to validate their accuracy. - User Training and Onboarding:

Cedra provides comprehensive training to ensure users are equipped to utilize the system effectively. - Go-Live and Real-Time Monitoring:

Once live, Cedra monitors equipment performance in real-time, providing predictive insights and alerting users to potential issues. - Ongoing Support and Optimization:

Cedra provides continuous support, refining AI models and optimizing the system as operational needs evolve.

Initial Assessment

Data Collection and Integration

Customization and System Setup

Model Training and Testing

User Training and Onboarding

Go-Live and Real-Time Monitoring

Ongoing Support and Optimization

CONCLUSION

Cedra’s AI-powered Predictive Maintenance offers businesses a comprehensive solution for optimizing asset management and reducing operational costs. With real-time monitoring, AI-driven insights, and seamless integration with existing systems, Cedra enables businesses to anticipate equipment failures, extend asset lifespans, and maintain optimal operational efficiency.

The continuous evolution of AI models ensures that Cedra’s predictive maintenance solution remains aligned with changing business needs, delivering long-term value and sustainability.

24/7 Availability:

Ensuring customer inquiries are addressed regardless of time or day

Personalization:

Tailors interactions based on user preferences, past behaviors, and personal data for a customized experience.

Scalability:

Easily scalable to handle increasing volumes of queries or tasks, suitable for growing businesses.

Cost-Efficiency:

Reduces the need for a large human support team, cutting down on operational costs.

Cross-Platform Integration:

Can be integrated across various platforms and devices, from smartphones to desktops and IoT devices.